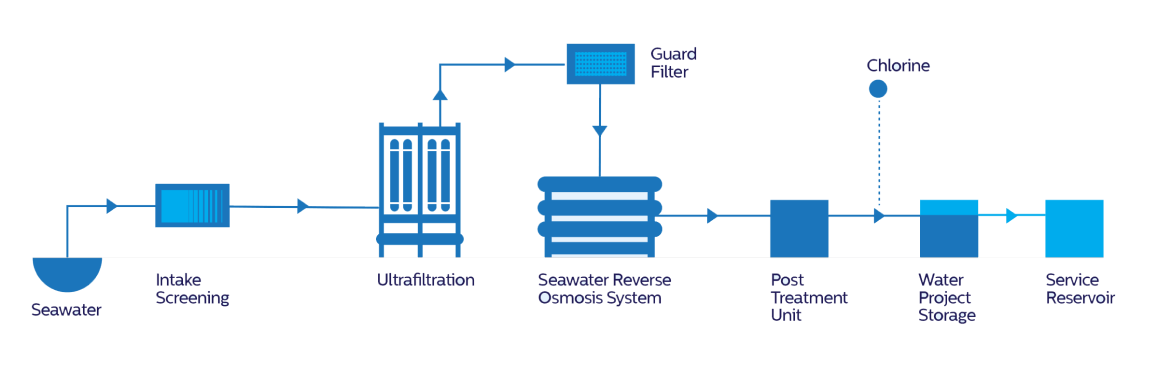

How desalination works?

Desalination is the process of removing salt and other minerals from water to make it suitable for drinking or for industrial use. In water-stressed areas, desalination can be a sustainable solution that eliminates the need to transport water over long distances.

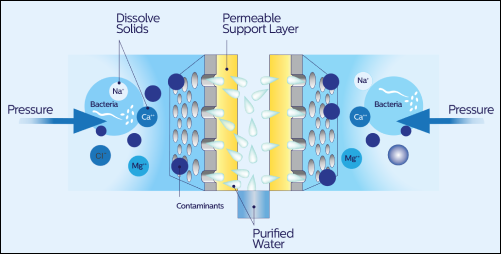

Membrane-based desalination uses semi-permeable reverse osmosis membranes and pressure to separate salts from water. Reverse osmosis technology uses less energy than thermal distillation, and technology enhancements have led to a reduction in over all desalination costs over the last decade.